What materials can be made into biomass pellets?

The raw material used for making fuel pellets is called biomass. Biomass is any living or recently dead material that can be used as fuel.There are a wide range of raw materials which can be made into biomass pellets, including wood sawdust, chips, shavings, branches, logs, palm EFB, palm fiber and ···

What is matrix for pellet mill?

It is a professional terminology referring to a key part of pellet mill. It can be seen as the mold of pelleting. The structure and quality of matrix largely affect the performance of pellet mill and quality of finished biomass pellets. Matrix is generally made from high hardness alloyed s···

What are rollers for pellet mill?

Rollers work with matrix, constituting a die-roller assembly. There are two rollers(or three rollers) and one matrix mounted in the pelleting chamber. For Ring Die Pellet Mill, the rollers are subject to the matrix. During the pelletizing process, high pressure is produced betwee···

What is compression ratio of matrix for pellet mill?

Compression ratio is related with the diameter and length of matrix pore. It is a very key factor which affects the effects of pelleting. Different materials have different requirements on matrix design of thickness and pore size. A suitable compression ratio of matrix to your own materials wil···

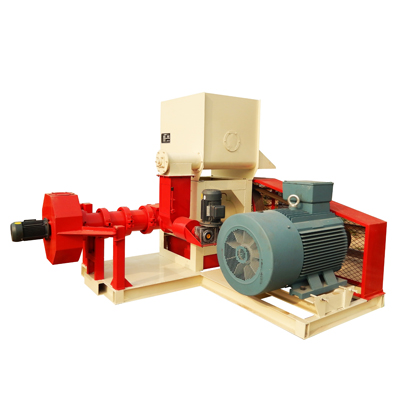

What is the structure of Ring Die Pellet Mill?

A Ring Die Pellet Mill has a ring shaped die, and a set of rollers. The die it positioned vertically, with the two rollers set within the die, applying force to the inner edge of the ring die. Due to the vertical roller and die position a motor is required to meter raw material into the centre ···

What is the working principle of Ring Die Pellet Mill?

Powder biomass materials enter into the place which is among ring die and pressing rollers. The running ring die drives pressing rollers to squeeze the powder material out of the small holes of ring die automatically. After the pelleting process, powder materials will be pressed(formed) into pe···

What is the advantage of Ring Die Pellet Mill?

Firstly Ring Die Pellet Mill does not suffer uneven roller and die wear as the inner and outer edge of the roller covers the same distance. For this reason Ring Die Pellet Mill is preferred for medium & large scale production as the costs of roller and die consumables are perceived to ···

What factors affect the service-life of matrix and rollers?

The life of matrix and roller are determined by several factors. Firstly the matrix metal will influence abrasive resistance and breakage resistance. Abrasive raw materials lead to shorter matrix and roller life. The roller gap also affects the life of consumables. If the rollers···

What main factors affect the pelleting production and quality of finished pellets?

1. Features of raw materials: species, volume, particle size, moisture2. Compression ratio and smoothness of matrix3. Feeding flow4. Distance between matrix and rollers5. Stable power supply6. Lubricate bearings, matrix, rollers, etc7. Operation and maintenance of ···

How to make biomass pellets?

This guide will follow the process step-by-step to produce quality fuel pellets. It states the equipment used at each stage. The step-by-step pelleting process is as follows: 1. Size Reduction: Chippers/Shredders, Hammer Mills 2. Material Transportation: Fans, Cyclone Separa···

How to make pellet mill maintenance?

The equipment used in pellet production is exposed to high pressures and temperatures, extreme forces are placed on the equipment and proper maintenance can increase equipment life and reduce energy demand.The pellet mill particularly has many bearings, which reach high temperatures during oper···

Can you provide on-site installation,commissioning and training service?

Yes, we provide you proressional on-site installation, commissioning & training service at your local workshop. But the related costs are not included in the proposal. The related costs mainly include round-trip air ticket, Visa expense, hotel,meal & traffic expense at Buyer’s···